-

सिकंदरविश्वसनीय आपूर्तिकर्ता

सिकंदरविश्वसनीय आपूर्तिकर्ता -

लुईयह आपके साथ काम करने के लिए एक खुशी रही है

लुईयह आपके साथ काम करने के लिए एक खुशी रही है

उच्च तापीय दक्षता क्षैतिज बॉयलर इकोनॉमाइज़र, 1 वर्ष की वारंटी और सर्पेन्टाइन ट्यूब डिज़ाइन के साथ

निःशुल्क नमूने और कूपन के लिए मुझसे संपर्क करें।

व्हाट्सएप:0086 18588475571

वीचैट: 0086 18588475571

स्काइप: sales10@aixton.com

यदि आपको कोई चिंता है, तो हम 24 घंटे ऑनलाइन सहायता प्रदान करते हैं।

x| प्रकार | प्राकृतिक परिसंचरण | संरचना | पानी की नाली |

|---|---|---|---|

| दबाव | उच्च दबाव | भाप उत्पादन | अधिकतम 60 टन/घंटा |

| शैली | क्षैतिज | ईंधन | कोयला आधारित |

| उत्पादन | गर्म पानी | सामग्री | विशेष बॉयलर स्टील प्लेट |

| ऊष्मीय दक्षता | 92.4%--94.5% | कार्य का दबाव | उच्च दबाव |

| वज़न | 1-20 टन | गलाने की प्रक्रिया | ईएफ+एलएफ + वीडी |

| सामग्री मानक | एएसटीएम, एन या आईएसओ आदि। | यूटी मानक | ASTM A388 या EN10228, आदि |

| प्रक्रिया | सामग्री-> इंगॉट -> हॉट/कोल्ड -रोलिंग-> हीट ट्रीटमेंट (सामान्यीकरण+ टेम्परिंग) -> निरीक्ष | ||

| प्रमुखता देना | उच्च तापीय दक्षता बॉयलर इकोनॉमाइज़र,क्षैतिज बॉयलर अर्थशास्त्री,1 वर्ष की वारंटी सर्पेन्टाइन ट्यूब इकोनॉमाइज़र |

||

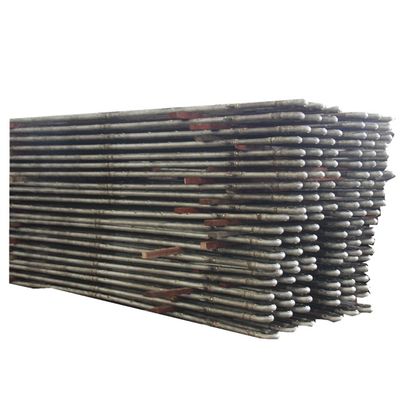

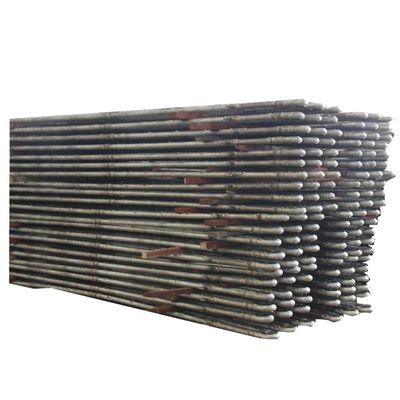

बॉयलर इकोनॉमाइज़र पंख वाले ट्यूबों के साथ हीट एक्सचेंज डिवाइस हैं जो तरल पदार्थों (आमतौर पर पानी) को उनके क्वथनांक से नीचे के तापमान पर गर्म करते हैं। हम तीन प्रकार के बॉयलर इकोनॉमाइज़र का निर्माण करते हैं:

- बेयर ट्यूब इकोनॉमाइज़र

- एच-फिन ट्यूब इकोनॉमाइज़र

- सर्पिल फिन ट्यूब इकोनॉमाइज़र

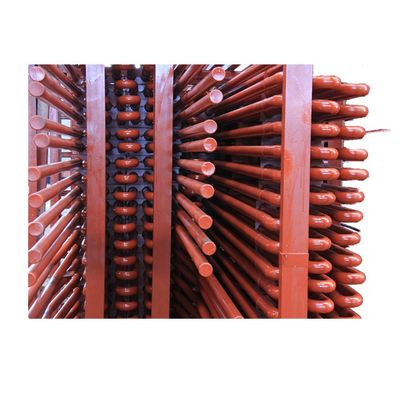

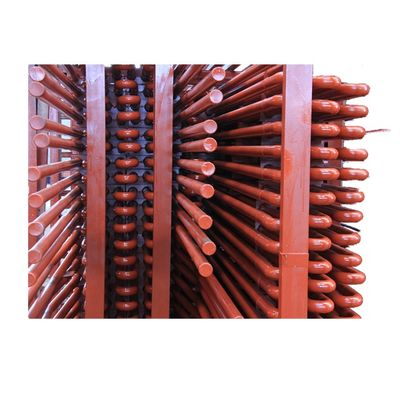

एच-फिन ट्यूब इकोनॉमाइज़र एक उच्च-दक्षता वाला हीट एक्सचेंजर है जिसमें एच-फिन ट्यूब होते हैं। बेयर ट्यूब इकोनॉमाइज़र की तुलना में, यह प्रदान करता है:

- बढ़ी हुई हीट एक्सचेंज एरिया

- आवश्यक ट्यूबों की संख्या कम हुई

- फ्लो स्पीड और घर्षण को कम करने के लिए विस्तारित फ्लू गैस फ्लो एरिया

एच-फिन ट्यूबों को बेहतर कठोरता के लिए डबल एच-फिन ट्यूब के रूप में बनाया जा सकता है, जिससे वे लंबी ट्यूब पंक्तियों के लिए उपयुक्त हो जाते हैं।

सर्पिल फिन इकोनॉमाइज़र में सर्पिल फिन ट्यूबों के साथ एक नया डिज़ाइन है जो गंभीर घर्षण मुद्दों को संबोधित करता है और सेवा जीवन को बढ़ाता है।

| विवरण | बॉयलर इकोनॉमाइज़र |

|---|---|

| सामग्री | मिश्र धातु इस्पात, कार्बन स्टील, SA210C, SA213T22, आदि। |

| सामग्री मानक | ASTM, EN या ISO आदि। |

| आयाम | अनुकूलन |

| वज़न | न्यूनतम: 10 टन अधिकतम: 1000 टन |

| प्रगलन प्रक्रिया | EF+LF + VD |

| प्रक्रिया | सामग्री→इन्गट→गर्म/ठंडा-रोलिंग→हीट ट्रीटमेंट (नॉर्मलाइजिंग+टेम्परिंग)→निरीक्षण→रफ मशीनिंग→UT→2nd हीट ट्रीटमेंट→फिनिशिंग मशीनिंग→निरीक्षण |

| UT मानक | ASTM A388 या EN10228, आदि |

- प्रभाव परीक्षण और लागू सामग्री जानकारी के साथ शक्ति गणना रिपोर्ट

- स्टील प्लेट, ट्यूब और इलेक्ट्रोड की 100% NDT (गैर-विनाशकारी निरीक्षण) रिपोर्ट

- बॉयलर की गुणवत्ता सुनिश्चित करने के लिए एक्स-रे, γ-रे और तरल प्रवेशक परीक्षण निरीक्षण रिपोर्ट (वेल्डिंग सीम)

- मानक कार्यशील दबाव और सुरक्षा को सत्यापित करने के लिए हाइड्रोलिक परीक्षण रिपोर्ट